Foxx Life Sciences

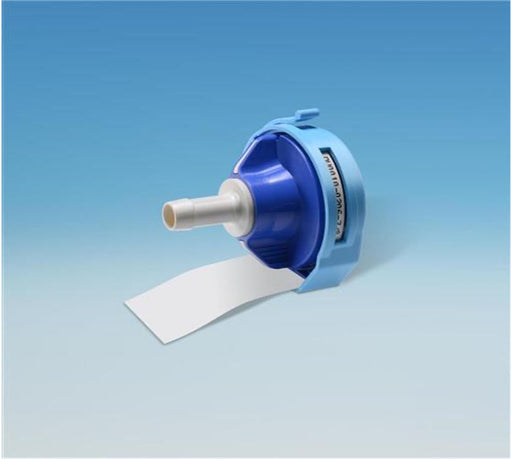

Kleenpak® Presto Sterile Connector, 3/8" HB, Polyethersulfone, PSC1G10

SKU:

With its intuitive operation, sterile connections can be to be carried out in a simple three-step operation, even in an unclassified environment, without compromising the sterility of the fluid paths.

Key design features such as the anti-actuation tabs and tamper-resistant protective cap give end users more confidence in operation and security of supply.

The Kleenpak Presto sterile connector brings enhanced levels of quality assurance with 100% inspection at point of manufacture that allows device traceability, as each device has its own serial number. The manufacturing process of Kleenpak® Presto sterile connectors brings an enhanced level of quality assurance, with the use of an automatic vision system that ensures the absence of defects in the membrane and membrane welding.

Available in a variety of sizes – 6.35 mm (¼ in.), 9.53 mm (⅜ in.), 12.7 mm (½ in.), 15.8 mm (⅝ in.), 19 mm (¾ in.) hose barb, and 12.7 mm (½ in.) sanitary connection – the Kleenpak Presto sterile connector can be used in upstream processing, downstream processing, and formulation and filling. Made from Bisphenol-A (BPA) free Polyethersulfone (PES) the Kleenpak Presto sterile connector is compatible with a wide range of process fluids and solvents.

Specifications

| Suplier Part number: | PSC1G10 | |||||||||

| Internal Diameter: | 0.32in (8mm) | |||||||||

| Connection: | 3/8in (9.53mm) hose barb | |||||||||

| O-Ring Material: | Platinum-cured silicone (in fluid path) | |||||||||

| Connector Body Material: | Polyethersulfone (PES) (in fluid path) | |||||||||

| Minimum Operating Temperature: | 2°C (35.6°F) | |||||||||

| Maximum Operating Temperature: | 60°C (140°F) | |||||||||

| Sterilization Conditions (Autoclave): | 75 minutes at 130°C | |||||||||

| Maximum Gamma Irradiation Dose: | 50 kGy | |||||||||

| Maximum Operating Pressure: | 3 barg up to 90 days; 4 barg up to 2 days | |||||||||

| Connector Format: | Genderless | |||||||||

Applications

• Media preparation and transfer

• Buffer preparation and transfer

• Transfer of inoculum to bioreactor

• Sampling during fermentation / cell culture

• Bioreactor harvest

• Sterile fluid transfer between unit operations

• Bulk handling of sterile material in non-classified environments

• Probe insertion into bioreactors, mixers and 3D biocontainers

• Sterile filtration manifolds

• Hybrid stainless steel and single-use system connection

• Connection of bulk sterile material to filling machine

• Sterile waste removal from process streams

Video

Share this Product

![[product-title]-Foxx-Life-Sciences](http://www.foxxlifesciences.com/cdn/shop/products/1103-RLS_512x512.jpg?v=1531405251)

![[product-title]-Foxx-Life-Sciences](http://www.foxxlifesciences.com/cdn/shop/products/1102-RLS_512x512.jpg?v=1531405253)